CE Certificate China Supplier Plastic Water Tank Machinery

Basic Info

| Model NO. | YK 2000L-3 |

| Warranty | 1 Year |

| Type | Extrusion Blow Molding Machine |

| Raw Material | HDPE |

| Making Method of Parison | Extrusion-Blow Molding |

| Automation | Automatic |

| Computerized | Computerized |

| Certification | CE, ISO9001:2008 |

| After-sales Service | Engineers Available to Service Machinery Overseas |

| 2000L | Three Layer |

| Automatic | Touch Screen |

| Plastic Processed | Hmhdpe HDPE |

| High Efficiency | Fast Delivery |

| High Configuration | Siemens |

| Parison Control | Moog |

| Advantages | High Speed Saving Energy Low Cost |

| Machine Test Report | Provided |

| After-Sales Service Provided 2 | Training or Video Technical Support |

| Weight | 38 Ton |

| Transport Package | Wooden Package |

| Trademark | YANKANG |

| Origin | Qingdao |

| HS Code | 8477301000 |

| Production Capacity | 30 Sets/Year |

Product Description

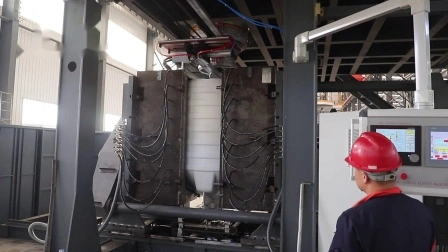

The 2000L water tank blow molding machine can be used to produce water tanks from 500L to 2000L in 1-6 layers.

1, Adopt pressurized cylinders for the entire series. Optimize the structure of the machine, and increase productivity while providing a more powerful clamping force.

2. Use a more energy-efficient servo-hydraulic system. It saves energy by more than 40% and reduces noise.

3. Adopt advanced electromagnetic induction and infrared heating system. Safe and reliable. Save energy 30%-50%.

4. Use famous brands products from Germany and America for our machine components of electrical, hydraulic, pneumatic, and control.

Technical Parameter of 2000L Water Tank Blow Molding Machine

Output For Each Capacity

2000L water tank blow molding machine can use 500L,700L, 1000L,1500L, and 2000L blow molds.

Can be used for production:500L tank 16-18 PC/H,750L tank 14-16 PC/H,1000L tank 10-12 PC/H,1500L tank 9-12 PC/H and 2000L tank 8-9 PC/H.

For more production details:

| Capacity | Product | Unit | Weight | Thickness |

| 500L Tank | 16-18 | PC/H | 6-10KG | 2.5m |

| 750L Tank | 14-16 | PC/H | 10-15KG | 2.5-3m |

| 1000L Tank | 10-12 | PC/H | 16-20KG | 3-3.5mm |

| 1500L Tank | 9-11 | PC/H | 20-30KG | 3-4mm |

| 2000L Tank | 8-9 | PC/H | 30-40KG | 4-5mm |

Technical data for YK 2000L series

In the table below, the data of the blow molding machine of YK 2000L-3 layers, YK 2000L-4 layers, YK 2000L-5 layers, YK 2000L-6 layers are listed.

| Technical Data for YK 2000L Series | ||||||

| Model No. | YK 2000L-3 | YK 2000L-4 | YK 2000L-5 | YK 2000L-6 | ||

| Specifications | 3 layers | 4 layers | 5 layers | 6 layers | ||

| Extruders | Screw Diameter | ∮90*3 | ∮90*4 | ∮90/90/60/90/90 | ∮90/90/60/90/90 | |

| Motor | 55*3kw | 45*4kw | 45/45/18.5/45/45kw | 45/45/18.5/45/45kw | ||

| Plasticizing Capacity | 400kg/h | 400kg/h | 400kg/h | 400kg/h | ||

| L/D | 32/1 | 32/1 | 32/1 | 32/1 | ||

| Max Screw Speed | 60RPM | 60RPM | 60 RPM | 60 RPM | ||

| Die Head | Accumulator Capacity | 80L | 80L | 80L | 80L | |

| Heating Load | 83.2kw | 65kw | 71.9kw | 78.8kw | ||

| Max. Parison Weight | 60kg | 60kg | 60 kg | 60kg | ||

| Clamping Unit | Clamping Platen Size | 1700x1800mm | 1700x1800mm | 1700x1800mm | 1700x1800mm | |

| Max Mould Size | 1600x1900mm | 1600x1900mm | 1600x1900mm | 1600x1900mm | ||

| Clamping Force | 1800 KN | 1800 KN | 1800 KN | 1800 KN | ||

| Mould Thickness | 1010-1600mm | 1010-1600mm | 1010-1600mm | 1010-1600mm | ||

| Hydraulic System | Hydraulic Drive Motor (Main) | 42kw | 42kw | 42kw | 42kw | |

| Hydraulic Drive Motor (Parison Control) | 7.5kw | 7.5kw | 7.5 kw | 7.5 kw | ||

| Oil Tank Capacity | 1200L | 1200L | 1200L | 1200L | ||

| Machine Weight | 38 Ton | 42 Ton | 46 Ton | 50 Ton | ||

| Dimension | L x W x H | 11m*13m*6.2m | 11m*13m*6.2m | 11m*13m*6.2m | 11m*13m*6.2m | |

| Total Power | 384kw | 448kw | 495 kw | 516kw | ||

| Average Power Consumption | 192kw | 235kw | 255 kw | 280kw | ||

SERVICE

Special Design

Qingdao Yankang Plastic Machinery is the largest professional blow molding machine integration enterprise in China, including product research and development, production, sales, and after-sales service. It is the pioneer and leader of the large blow molding machine. The company has its own professional research and development base.

The core technology is 100% independent R&d innovation. According to the needs of customers and the situation of the site, we can use the private customized model to create suitable products for customers.

Customized products: various blow molding machines including water tanks, IBC, road barriers, pallets, etc, and blow molds with different capacities.

After-sales Service

TRAININGThe Buyer could dispatch their operators to the Seller's factory for training, including machine operation, maintenance & simple repairs;Or against the requests of the Buyer, the Seller's technician could train the Buyer's operators in the Buyer's factory during the periods of installing & adjusting;

INSTALLATION & ADJUSTMENTThe Seller could dispatch an engineer against the requests of the Buyer to install and adjust the machines for one week(free of charge) in the Buyer's factory. After one week, if the Buyer still needs the training,$100 should be paid to the engineer.The Buyer should make a reservation in advance before delivery of the machines;The Buyer should pay for the engineer's food & board while installation in the buyer's factory. And the Buyer should also pay for the air ticket for the engineer.

GUARANTEE The guarantee time is one year after the machines normally work in the Buyer's factory if only the problem is caused due to quality control or any reason by the Seller. We will supply replaced parts free of charge and our engineers will guide you on how to solve the problems.

Sales Network

Now, Qingdao Yankang Plastic Machinery has successfully occupied the world's major markets. With excellent quality assurance and perfect after-sales service, it has won high praise from customers at home and abroad. The company's products have spread to 45 countries and regions. These include Southeast Asia, the Middle East, Europe, the Americas, Australia, Africa, and so on. It has become the well-deserved "leader" in the blow molding machine industry in China.

FAQQ1: What is the warranty of the machine?A1: The whole machine's warranty period is 12 months and key parts will be dependent. Q2: Are you an integrated supplier for extrusion molding machines, mold, and auxiliary?A2: Yes, we can provide the complete solution line to customers according to the customer's requirements.

Q3: How about the quality control in your factory?A3: Yankang has the SOP (Standard Operation Procedure) and all the production steps must follow up this SOP. Every machine needs at least automatic running over 72 hours and must be inspected carefully before shipment..Q4: Will you offer the pre-sales service?A4: Yes, we have an experienced pre-sales team to support customers not only including machine, mold, and auxiliary selection but also water .electrical, machine layout in the factory, etc.Q5: What about the after-service? Will you send your engineer to my country to help commission and install the machine?A5: Surely, we have many experience technical engineers for oversea service, they would help you install machines and support training to workers also. Currently, we provide visits online by video call.Q6: What is the delivery time of the machine?A6: Actually, the delivery time of the machines is depended on the machine options. Normally, the delivery time of a standard machine could be within 2-3 months.

Q7: Mold trial will be available in the Yankang factory?A7: Yes, the Customer can send the mold to the Yankang factory and test it.Q8 . Do you provide any spare parts with the machine?A8: Yes, Yankang will provide one set of standard spare parts to customers.