China Factory Supply 6cavity Pet Blowing Machine 10000bph

Basic Info

| Model NO. | FG-6 |

| Making Method of Parison | Stretch Blow |

| Automation | Automatic |

| Computerized | Computerized |

| Certification | CE, ISO9001:2008 |

| After-sales Service | 1 Year |

| Cavity Number | 6 |

| Hourly Output | 10000bottles/Hour(@500ml) |

| Working Power | 30kw |

| High Pressure Require | 6m3/30bar |

| Motors | Servo Motor Control |

| Blowing Valve | American Parker |

| Electrical Element | Mistubishi/Siemens |

| Transport Package | Covered by PE Film |

| Specification | FG-6 |

| Trademark | Faygo |

| Origin | Jiangsu Zhangjiagang |

| HS Code | 84779000 |

| Production Capacity | 9000-10000bph |

Packaging & Delivery

Package size per unit product 360.00cm * 110.00cm * 240.00cm Gross weight per unit product 3500.000kgProduct Description

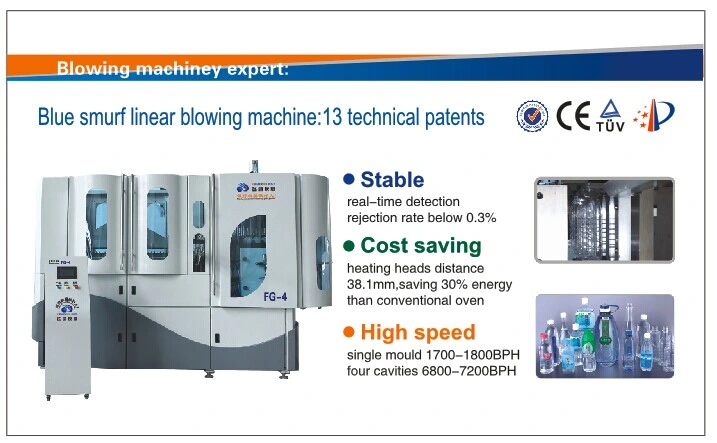

New Generation PET Bottle Blowing Machine

I. Each Year, We Guarantee Your Bottle Making Factory:

1) Output increased by 50%2) Waste bottle rate below 0.3%3) 20,000USD saved by power consumption4) blowing machine maintain cost below 800USD

High speed 6cavity 9000-10000BPH PET bottle blow molding machine

Specifications

1.Model: FG-6

2.Capacity:9000-10000B/H

3.Bottle type:200ml-2000ml

FG-6 PET bottle blowing machine

| Main Parameter | ||||

| Model | FG-6 | |||

| Capacity | Depend on bottle design | 9000-10000PCS/H(@500ml, 17g bottles) | ||

| Applicable Preform | Height | <330mm | ||

| Neck | 20mm-38mm | |||

| Applicable Bottle | Neck | 20-25mm | ||

| Volume | Max. 2Liter | |||

| Height | Max. 328mm | |||

| Diameter | Max. 105mm | |||

| Electric consumption | Install power | 51kw | ||

| Operating power | 30kw | |||

| Air consumption | Pressure | 3.0MPa | ||

| Capacity | 6m3/min | |||

| Mold Chiller | Pressure | 4-6Bar | ||

| Temperature | 6-13ºC | |||

| Flow | 45L/min | |||

| Oven Chiller | Pressure | 4-6Bar | ||

| Temperature | 6-13ºC | |||

| Flow | 26L/min | |||

| Machine Dimension | L*W*H | 4300*1000*2300mm | ||

| Weight | 4000kg | |||

| Main electrics | ||||

| Pneumatic part& Cylinder | Valve | Germany | ||

| Electric part | PLC | Japan Mitsubishi | ||

| Servo System | Japan Panasonic | |||

| Frequency inverter | Japan Mitsubishi | |||

| Operating system | Japan Mitsubishi | |||

| Touch screen | Japan Mitsubishi | |||

| Blowing | Valve | Japan Parker | ||

| One-way Valve | German | |||

| Throttle Valve | German | |||

| Reducing Valve | German DURAY | |||

| Note: All the electrical components adopts CE, UL, CCC approved international Advanced high-tech product | ||||

I. Brief Introduction:

FG4 is the new generation of linear blowing machine. Comnpared with traditional blowing machine, It has 3 improvement:

1)High speed: China first blowing machine whose single mold speed can reach 1800 BPH. FG4 has 4 cavities, production speed is 6500-7200BPH. FG6 has 6cavity, speed is 9000-10000bph. FG8 is 8cavity, speed is 12000-13000bph2) Energy saving: It has only 2 lamp boxes( based on 4cavity), at least 20000USD can be saved per year, electrical ammeter is equipped, you can know how much every single bottle costs you. 3) High Reliability: Machine adopts modularized design principle, the movement is integrated in 3 sets servo motor, which promises this machine will have good condition under full load operation.

II. Technical Features:

1. Servo driving and cam linking movement blowing section:

The unique cam linking system integrates mold-opening, mold-locking and bottom mold-evevating in one movement, equipped with high speed servo motor, which greatly shortens the blowing cycle and accelerates the spped.

2. Minimize distance of heating heads,maximize the heating efficiency.

Heater distance in the heating oven is minimized to 38.1mm, compared with the conventional heating oven it can save more than 30% consumption.Equipped with the air cycling system and redundant heating discharge system it ensures constant temperature in the heating zone.

3. Efficient and soft perform inlet system,ensure the spped and preform protction.

By rotary and soft preform loading system, the speed of preform feeding is ensured, meanwhile, the preform neck is well protected.

4. Modularized design conception, convenient for maintenance and changing changeovers

The machine adopts modularized design concept to make it convenient and cost-saving for the maintenance and changing changeovers.

III.After sale Services

1) Stand-by engineers team to provide overseas installation and commissioning service.

2) 1 year warranty. During warranty, we provide free of charge for repairing cost.

3) Lifetime maintenance. After-sales department can provide life long maintenance service.

Company Profile

Jiangsu Faygo Union Machinery is a professional manufacturer of plastic machines.It occupied an area of 18000 square meters. With years of development,its products covers plastic extrusion lines, plastic blowing machine, plastic recycling machine, air compressor etc. Stick to the company idea is making good machine, being good person,Faygo Plast alwasy provide customers with high quality machines.Warmly welcome to visit our factory (next to Shanghai)!

Our Service

1.The machine will be tested and checked at our workshop before delivery.2.After one year, we will supply accessories are provided only one the cost price.3.Free Spare Parts : Digital instrument, Sealing, Stretching cylinder seal ring, Mould-adjustment wrench, Furnace temperature table, Furnace heating tube and other relative vulnerable part.4.Free production technology and process configuration.5.We can help you to design the product line, workshop and provide turn-key project.6.Installation: Experts' team to buyer's country after confirmation that the goods arrived in site and civil works completed get ready for installation. Funds for trip need to be payed by client and extra salary $100/day during the engineer's journey.7.Warranty: One year from the date of Installation or acceptance of the Plant whichever comes first

FAQ

Q: Your company is a transactional company or an industrial manufacture factory?

A: We are an industrial manufacture factory which locates in Zhangjiagang city.

Q: All of your products are made by your self or compacted via purchasing the others?

A: We have independent technical team who focus on making machines, all the products are made by our technical team.

Q: What is the ability of your factory?

A: About 100 lines per month.

Q: Do you have any other services about your products?

A: We have a lot of experience on making projects and specifications for our clients, also we have a fixed service system.

Q: How do you make the quotation for clients?

A: The price depends on quality and performance but the clients should be satisfied first.